About Hangzhou Delong Technology Inc.

Established in 2003, Hangzhou Delong Technology Inc. is an environmentally focused technology enterprise. We specialize in providing highly efficient solutions for organic waste gas abatement technologies and equipment to various industries worldwide, including pharmaceuticals, petrochemicals, and others. Our headquarters are based in Hangzhou, Zhejiang province, with our service network spreading across the country.

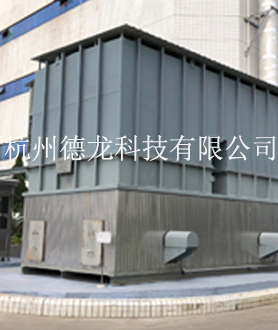

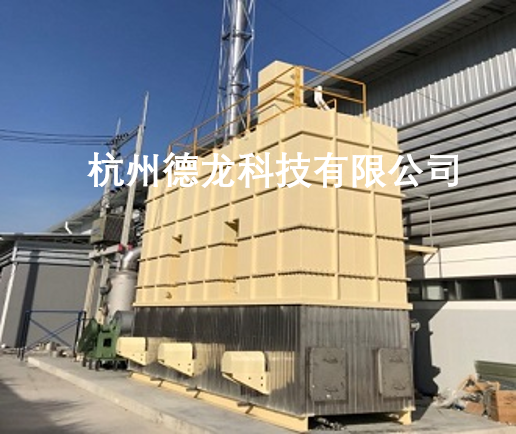

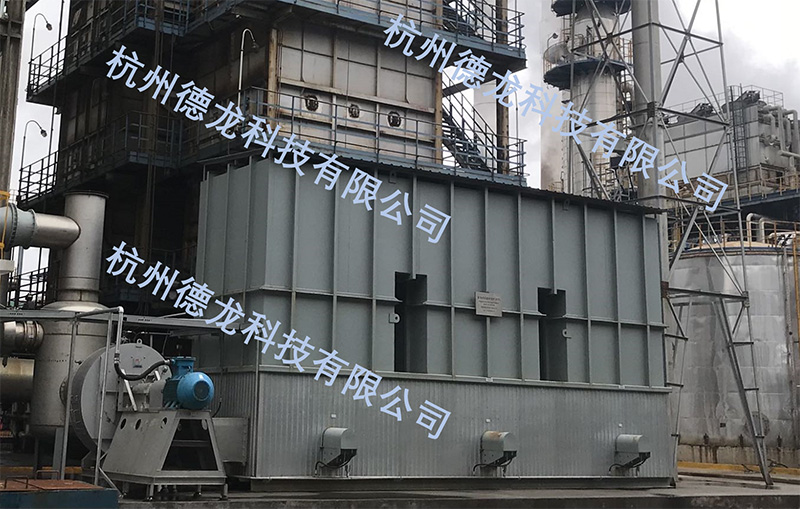

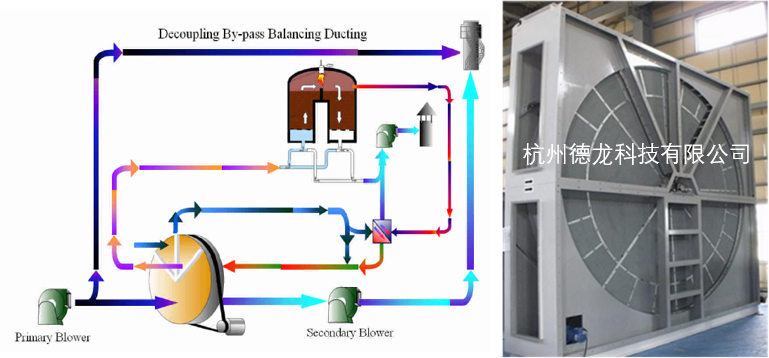

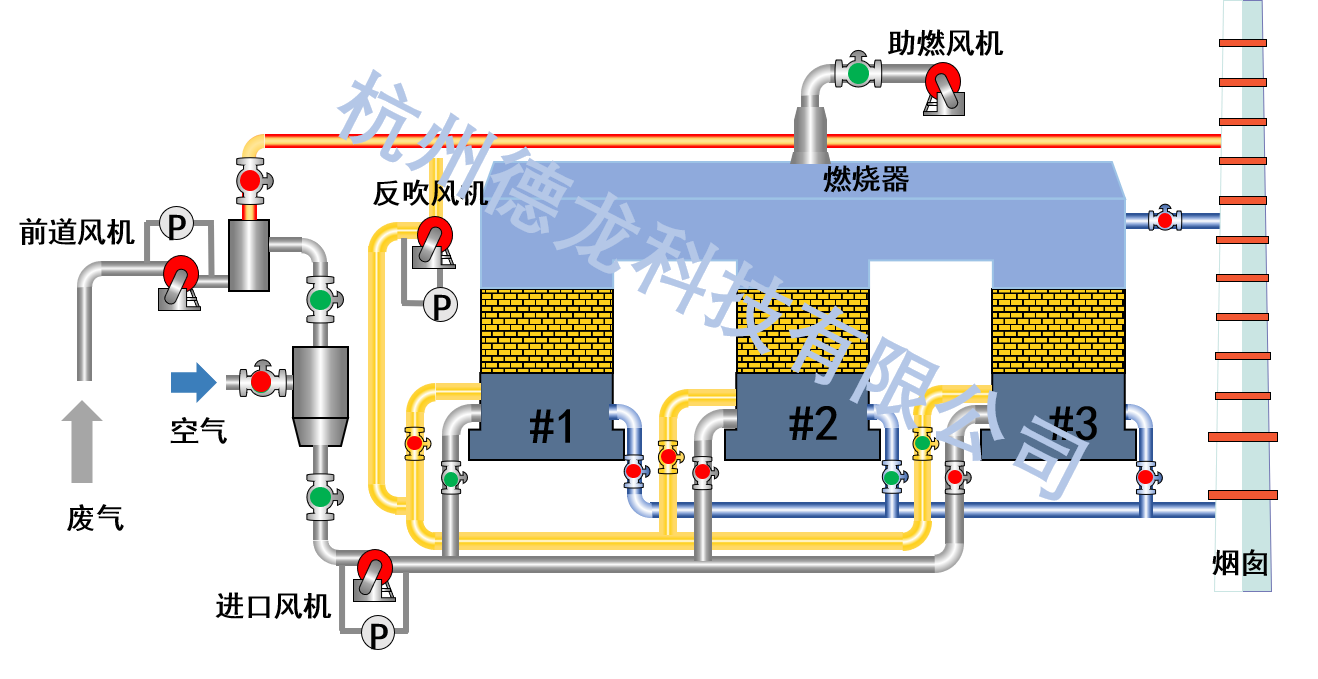

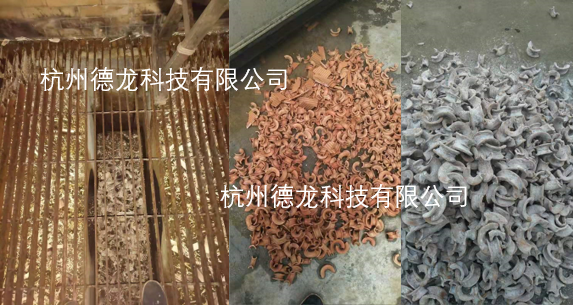

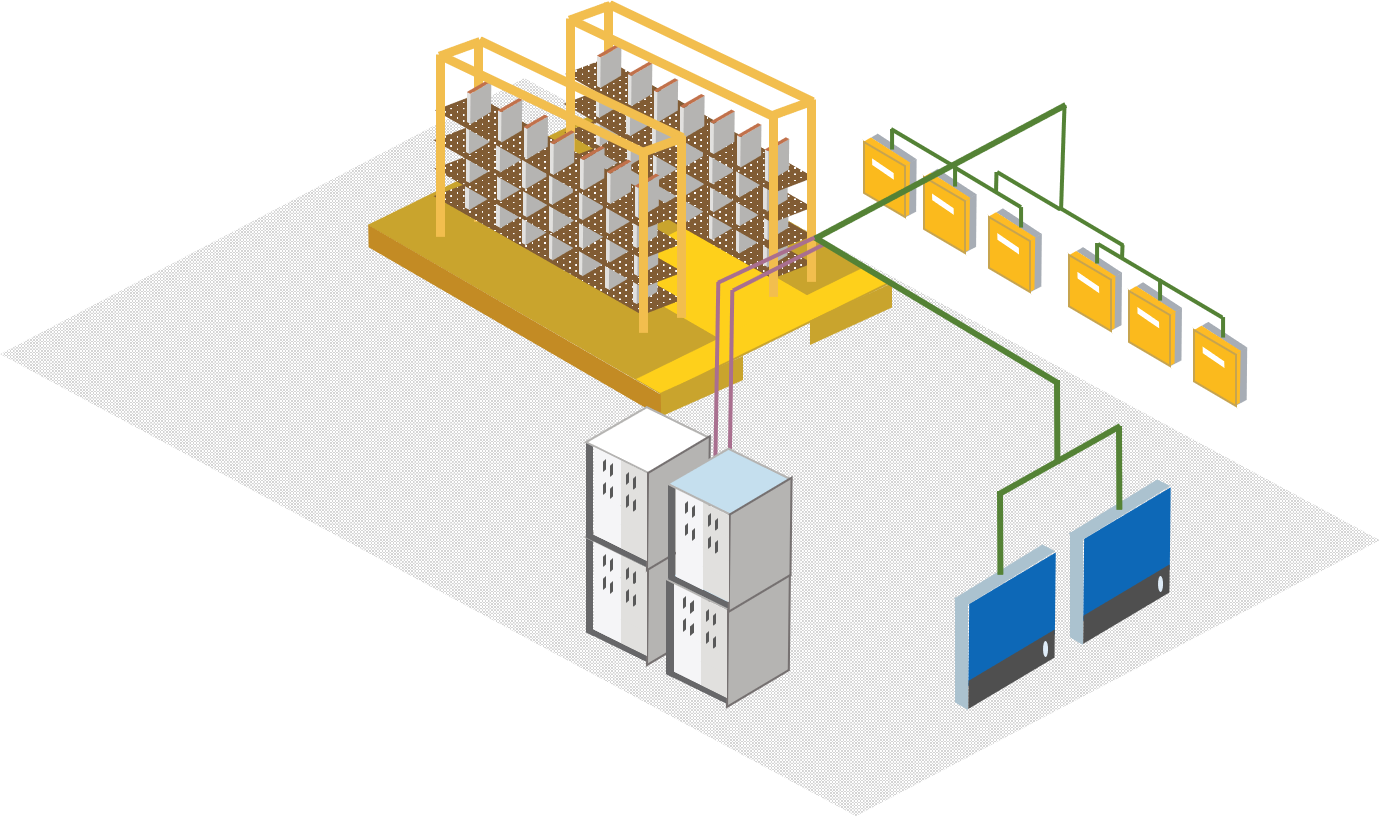

Our flagship product - the Regenerative Thermal Oxidizer (RTO), harnesses state-of-the-art Western technologies. It's a bespoke environmental apparatus designed with a keen understanding of the diversity and complexity of waste gas pollutants. The RTO has garnered widespread application both domestically and internationally.

As a member of the Zhejiang Environmental Protection Association and holder of the Zhejiang Ecological Environment Restoration Technology Council, we are distinguished by our ISO9001 national quality management system certification and numerous patented technologies. Our team consists of industry professionals who possess profound expertise and vast practical experience in waste gas abatement, committed to delivering precise, effective solutions to our clientele.

At Hangzhou Delong Technology Inc., we harness the power of technology for environmental conservation. We continually optimize our waste gas abatement technologies and equipment in our mission to enhance environmental quality in China and across the globe. We look forward to collaborating with more partners in our shared commitment to preserve the planet and foster a greener, sustainable future.